JDLVG600E_A10H

3-axis Machining for Glass Panels and Ceramic

- X/Y/Z Travel: 600/450/160mm

- Worktable Size: 640×590mm

- Max. Load: 100kg

- Spindle Specification: 32000rpm

- X/Y/Z Travel: 600/450/160mm

- Worktable Size: 640×590mm

- Max. Load: 100kg

- Spindle Specification: 32000rpm

JD105-32-HSK32(Standard) High-speed Precision Spindle

JD105-28-ISO25(Optional)

JD83-36-ISO20(Optional)

Highlights

Optimal Structural Design

The symmetrical and force closed-loop fixed beam portal structure makes the machine high rigidity and stable accuracy;

With large feeding space, it can be equipped with a four-axis or five-axis rotary table;

Equipped with side-placed stainless steel cutting fluid tank, the cooling effect is great due to the surround multi-headed nozzle for cooling;

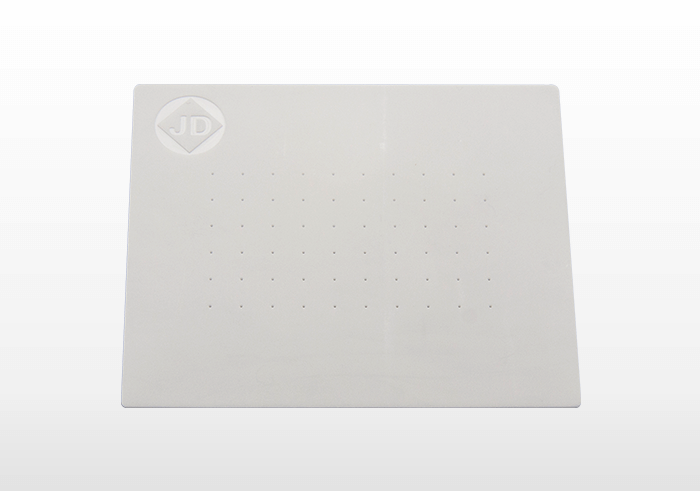

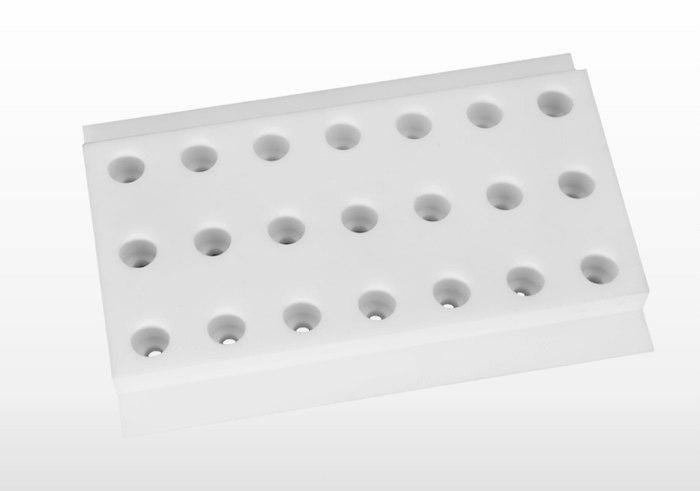

Equipped with vacuum filtration drainage device, vacuum negative pressure gauge, and vacuum fixture, it can quickly load and unload, and protect the glass panel and vacuum pump.

Outstanding Machining Performance

Equipped with self-produced motorized spindle, it has strong anti-vibration ability and can effectively reduce the amount of collapse of the glass contour;

The bed and beam adopt vibration-damping technology to ensure the machine tool has good precision retentivity;

Equipped with large-flow water pump and annular cooling nozzle, the tool cooling is comprehensive and sufficient, which can effectively extend the tool life.

Excellent Human-Machine Interaction

Machine protective cover equipped with automatic door;

Equipped with a side-placed cutting fluid tank for easy cleaning of the chips;

This company has a wealth of technical reserves in the field of glass machining, to provide customers with a all-around professional technical support.