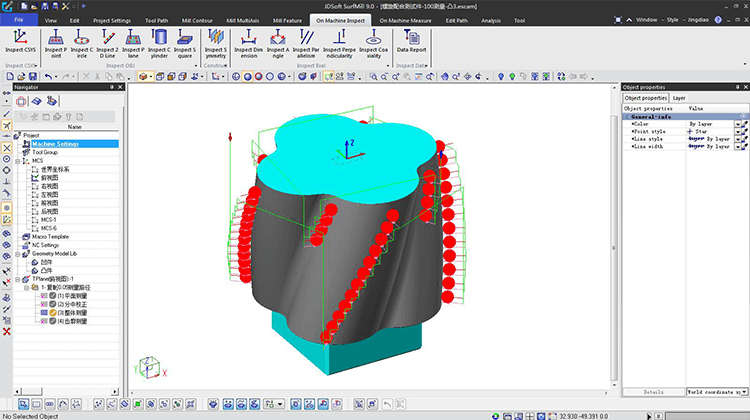

On-machine Measurement and Intelligent Modification Technology

OMIM

Digitization of Machining and Continuous Production

For parts quality control inspection is normally performed off machine which means interruption of production and instability considering manual operation.Jingdiao on-machine measurement and intelligent modification technology (OMIM) makes Jingdiao machine tools perceptive and smart based on our unique integration capability of CAD/CAM software and control system. With this technology, the operator, machine tool, process, and quality inspection, collaborates more effectively and achieve continuous production without any interruption.

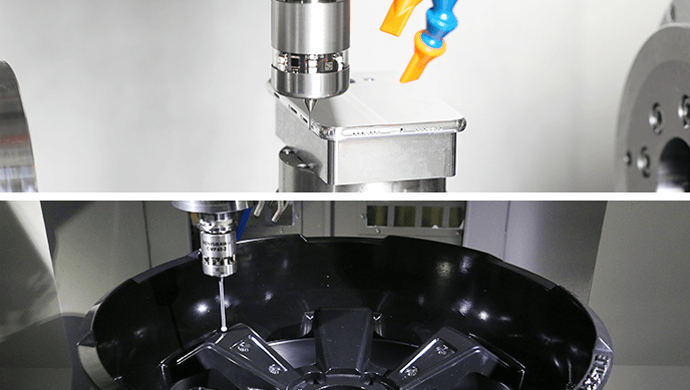

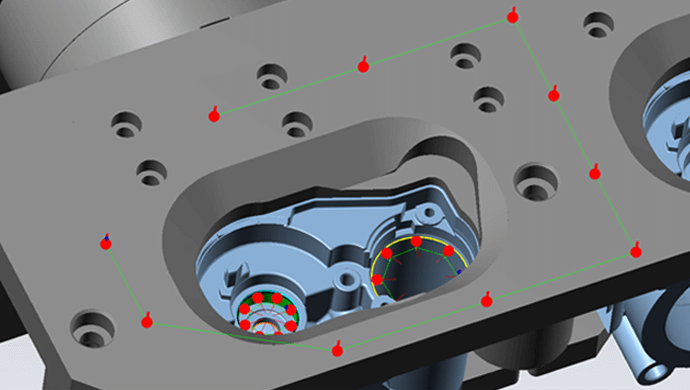

Process Tolerance Measurement and Quantification

+ READ MORE

Tolerance Measurement of Each Step

Intuitive Display in Control System

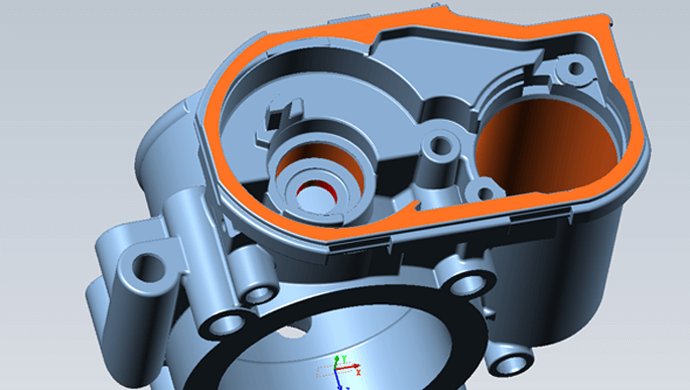

Intelligent Modification of Composite Error

+ READ MORE

Compensated Processing

+ READ MORE

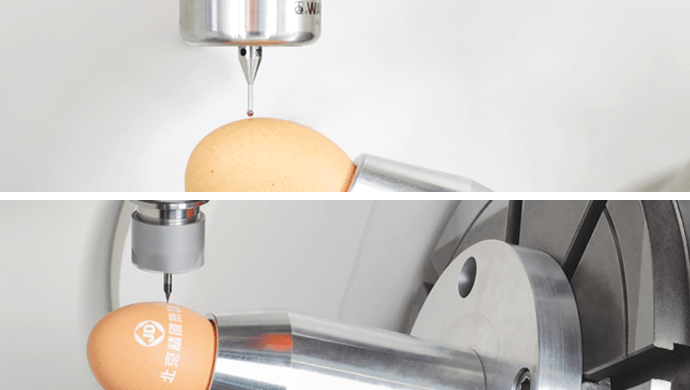

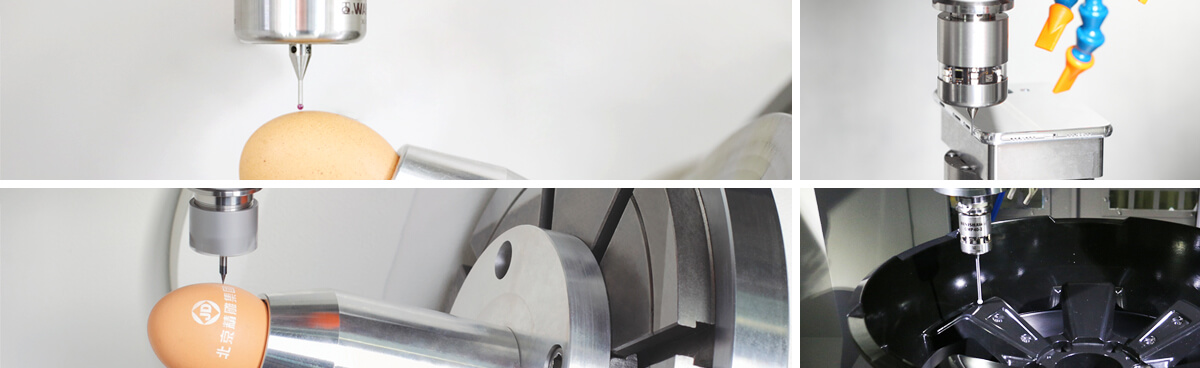

Shape-follow machining

Workpiece Alignment

+ READ MORE

Features to be inspected to align workpiece

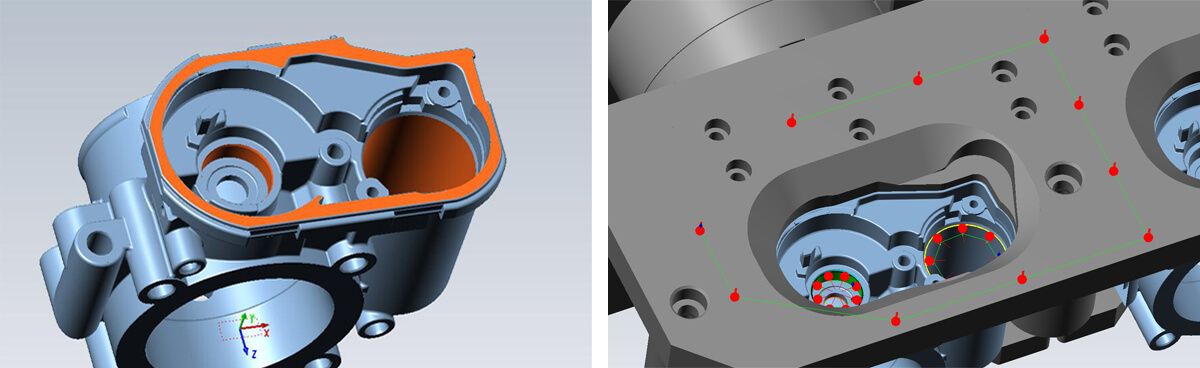

Manufacture Measurement

Integration

Since the introduction of OMIM, measurement has been transplanted into Jingdiao machine tools, thus a new manufacturing mode is created especially for massive production industry. By using functions like fool-proof inspection, tool condition monitoring, workpiece tolerance measurement and fixture condition monitoring, there is no interruption during processing, comprehensive quality control is achievable, unqualified products are no longer manufactured.

+ READ MORE

Less operator and no interruption after using OMIM

Manufacture Measurement Integration

Since the introduction of OMIM, measurement has been transplanted into Jingdiao machine tools, thus a new manufacturing mode is created especially for massive production industry. By using functions like fool-proof inspection, tool condition monitoring, workpiece tolerance measurement and fixture condition monitoring, there is no interruption during processing, comprehensive quality control is achievable, unqualified products are no longer manufactured.

+ READ MORE

Less operator and no interruption after using OMIM

Less operator and no interruption after using OMIM